What is Castellated Beams? ProtaStructure Design Guide

Castellated Beams: Use Cases and Famous Structures

In modern construction, innovation and efficiency are crucial elements for success. Among the many structural elements that have evolved to meet the demands of today’s architectural designs, castellated beams stand out for their unique combination of strength, flexibility, and cost-effectiveness. These beams, characterized by their signature web openings, have found a place in various high-profile projects worldwide.

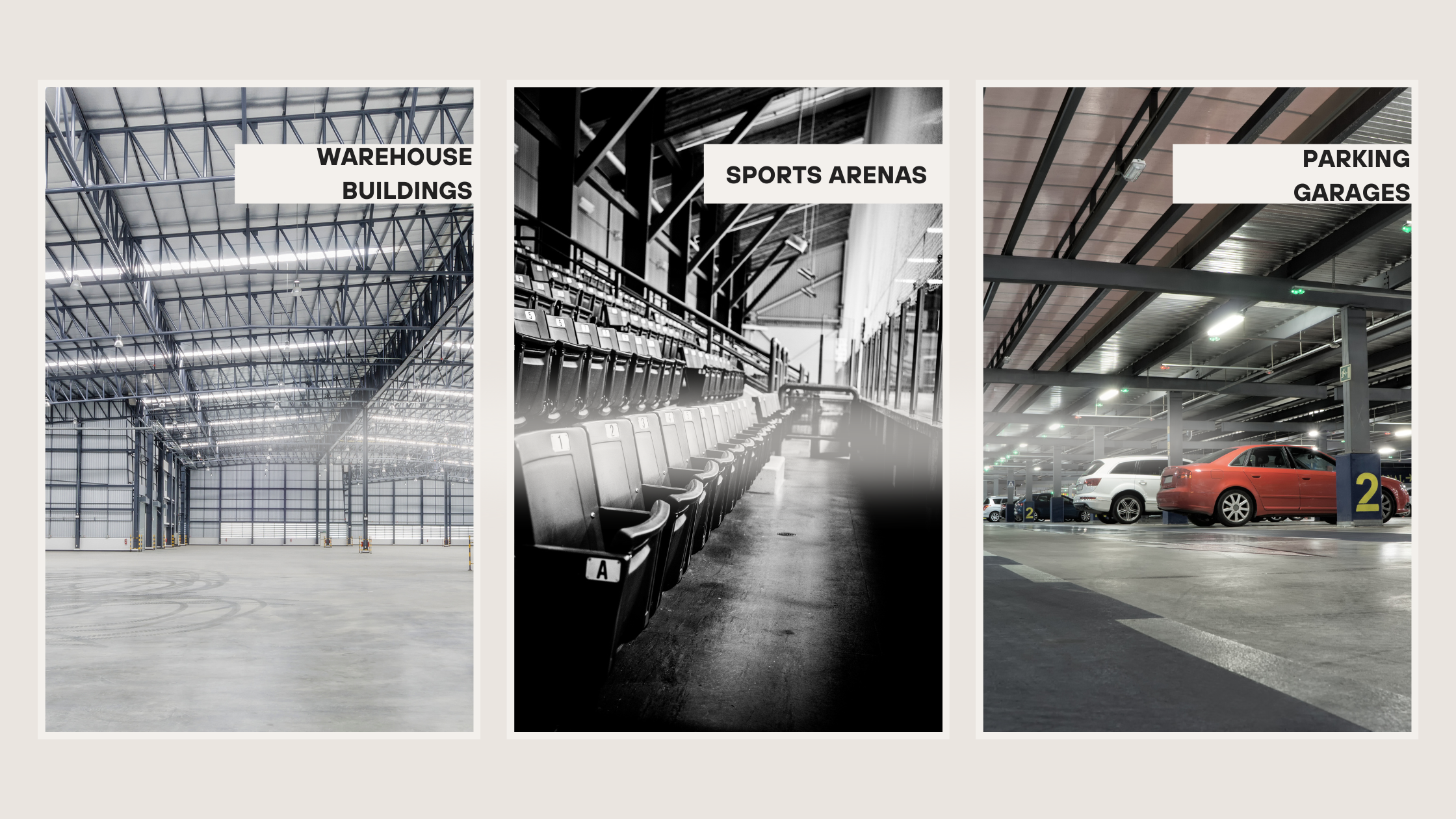

Use Cases

Warehouse Buildings

Why ? Warehouses require large, open spaces with minimal internal supports to maximize storage capacity and maneuverability. Castellated beams are ideal for this, offering long spans that reduce the need for interior columns.

Example: A modern distribution center uses castellated beams for its roof structure, providing a wide-open interior space that facilitates efficient storage and movement of goods.

Sports Arenas

Why ? Sports arenas demand unobstructed views and open spaces to accommodate large crowds. Castellated beams provide the necessary strength for long-span roofs while keeping the structure lightweight.

Example: In a recent sports arena renovation, castellated beams were used to support the roof structure, allowing for vast, column-free spaces that enhance spectator experience.

Parking Garages

Why ? Parking structures benefit from castellated beams due to their ability to span greater distances, reducing the number of columns and thereby maximizing parking space.

Example: A multi-level parking garage in an urban center utilizes castellated beams to provide wide driving lanes and increased parking efficiency, making the most of limited space.

Industrial Buildings

Why ? Factories and industrial plants need large, unobstructed spaces for heavy machinery and production lines. Castellated beams are perfect for this, offering the required strength with the added benefit of reduced material weight.

Example: A major manufacturing facility opted for castellated beams in its design, resulting in a spacious, efficient production environment that supports heavy loads and accommodates large equipment.

Commercial Buildings

Why ? In commercial buildings, flexibility in design is crucial. Castellated beams allow for large, open floor plans and easy integration of mechanical services like HVAC, plumbing, and electrical systems through the beam openings.

Example: A contemporary office building in a major city uses castellated beams throughout its floors, providing a sleek design with open, adaptable spaces that can be easily reconfigured as needed.

Bridge Construction

Why ? Bridges, especially those intended for pedestrian or light vehicular traffic, benefit from the strength-to-weight ratio of castellated beams. They provide the necessary support while minimizing the weight of the structure.

Example: A pedestrian bridge in a renowned park incorporates castellated beams, blending structural integrity with an aesthetically pleasing design that complements the natural surroundings.

High-rise Buildings

Why ? High-rise buildings demand strong yet lightweight structural components to support multiple floors. Castellated beams are often used in the floor structures to allow for open spaces and easy integration of utilities.

Example: In a towering skyscraper, castellated beams form the backbone of the floor structure, allowing for vast open office spaces and seamless integration of building services.

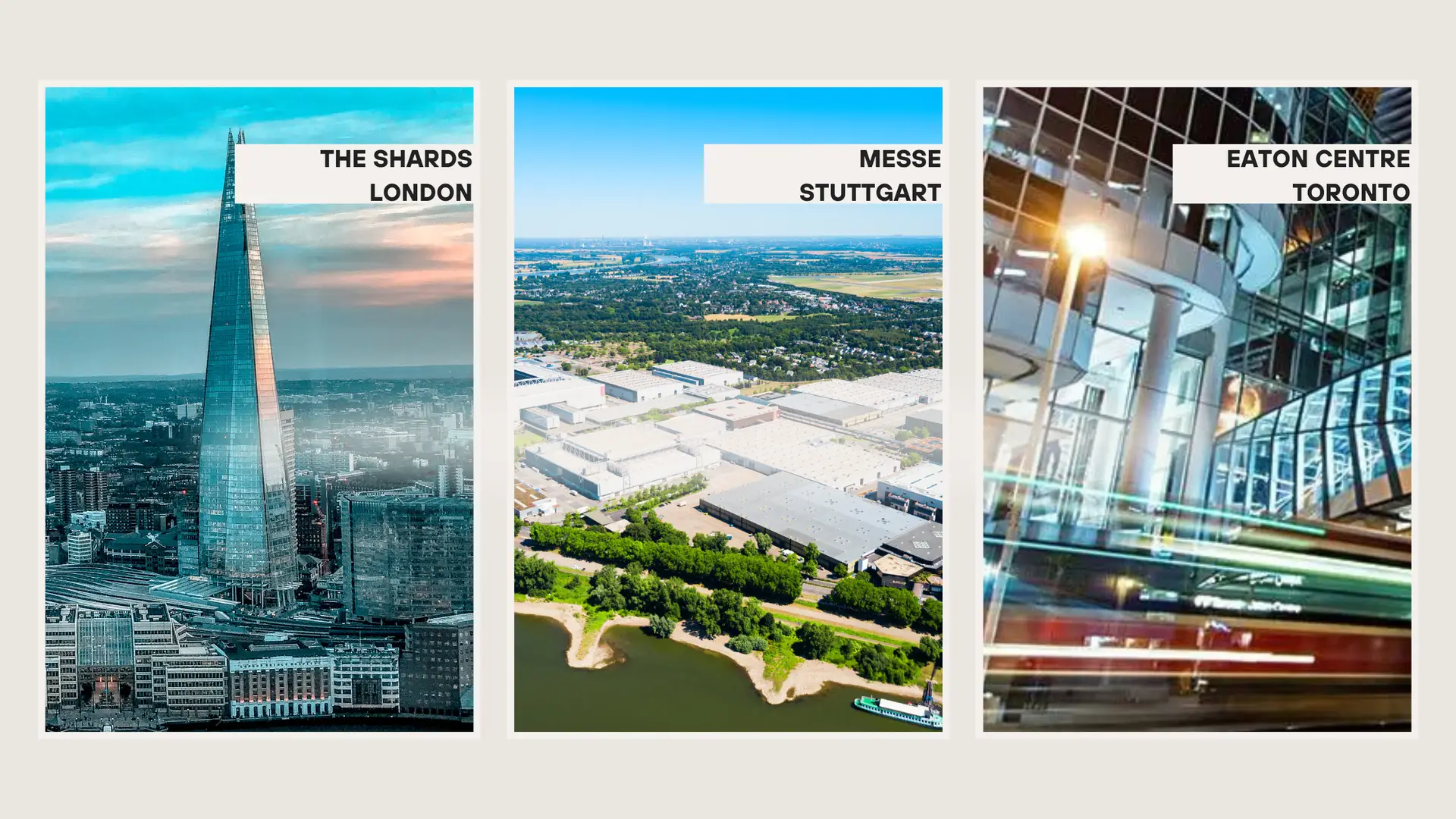

Famous Structures

While castellated beams are widely used in various types of construction, some famous structures have showcased their potential on a grand scale:

- The Shard, London: This iconic skyscraper, one of the tallest in Europe, utilizes castellated beams in its construction to achieve the necessary strength while maintaining a slender profile. The beams help support the building’s floors and contribute to its overall stability and flexibility.

- Messe Stuttgart, Germany: The Messe Stuttgart, a major convention center, features a vast roof structure supported by castellated beams. These beams provide the necessary span to cover large exhibition halls without intermediate supports, creating expansive, uninterrupted spaces ideal for large events.

- Toronto Eaton Centre, Canada: One of North America’s largest shopping malls, the Toronto Eaton Centre, employs castellated beams in its design to achieve wide-open retail spaces. The beams contribute to the mall’s airy, spacious feel, enhancing the shopping experience.

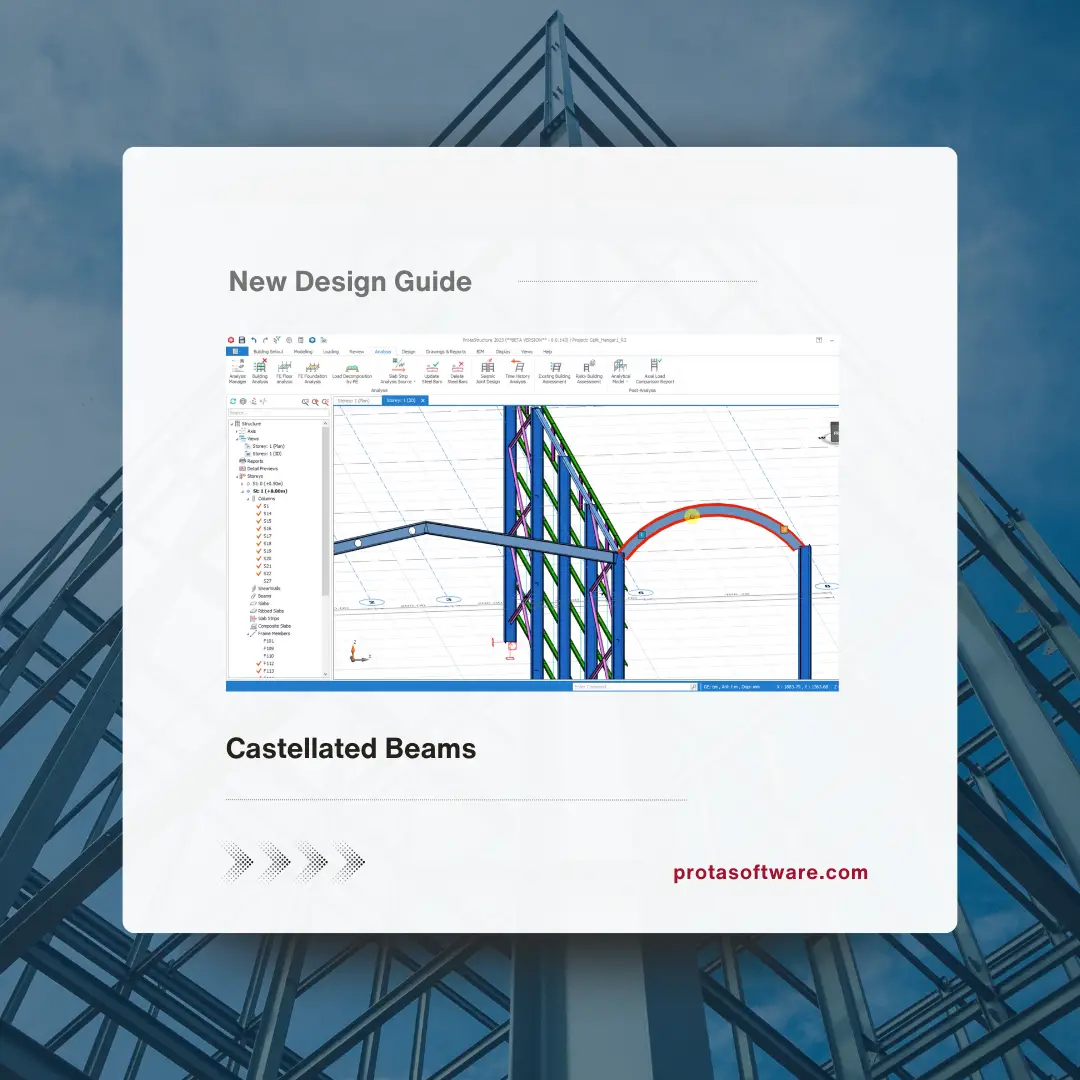

Understanding the ProtaStructure Design Guide: Castellated Beams – Version 2.0 July 2024

In the ever-evolving world of structural engineering, staying updated with the latest tools and techniques is crucial. One of the key resources in this domain is the ProtaStructure Design Guide for Castellated Beams, recently updated to Version 2.0 in July 2024. This guide is essential for engineers looking to enhance their knowledge and skills in designing with castellated beams using the advanced capabilities of ProtaStructure 2025. Key Features of ProtaStructure 2025 for Castellated Beams

ProtaStructure 2025 introduces new capabilities for modeling, analyzing, and designing castellated steel beams. These features allow engineers to efficiently incorporate castellated beams into their designs while ensuring structural integrity and compliance with relevant codes.

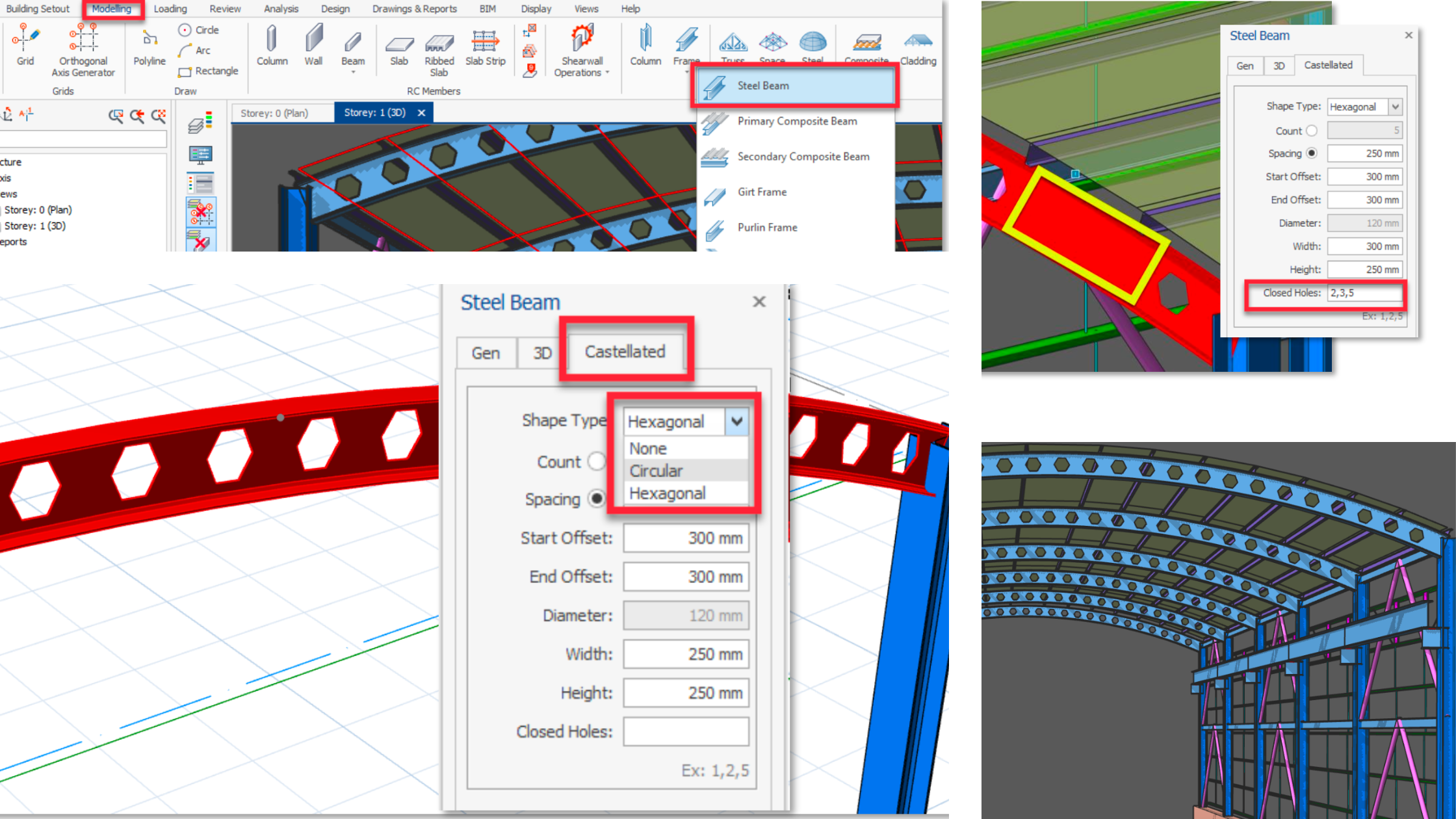

To insert a castellated beam in ProtaStructure, users can follow a straightforward process:

- Select the Steel Beam command from the Modeling > Frame ribbon tab.

- Insert a linear or curved frame member.

- Switch to the Castellated tab in the Frame Properties window.

- Choose between hexagonal or circular openings and specify the necessary dimensions and spacing.

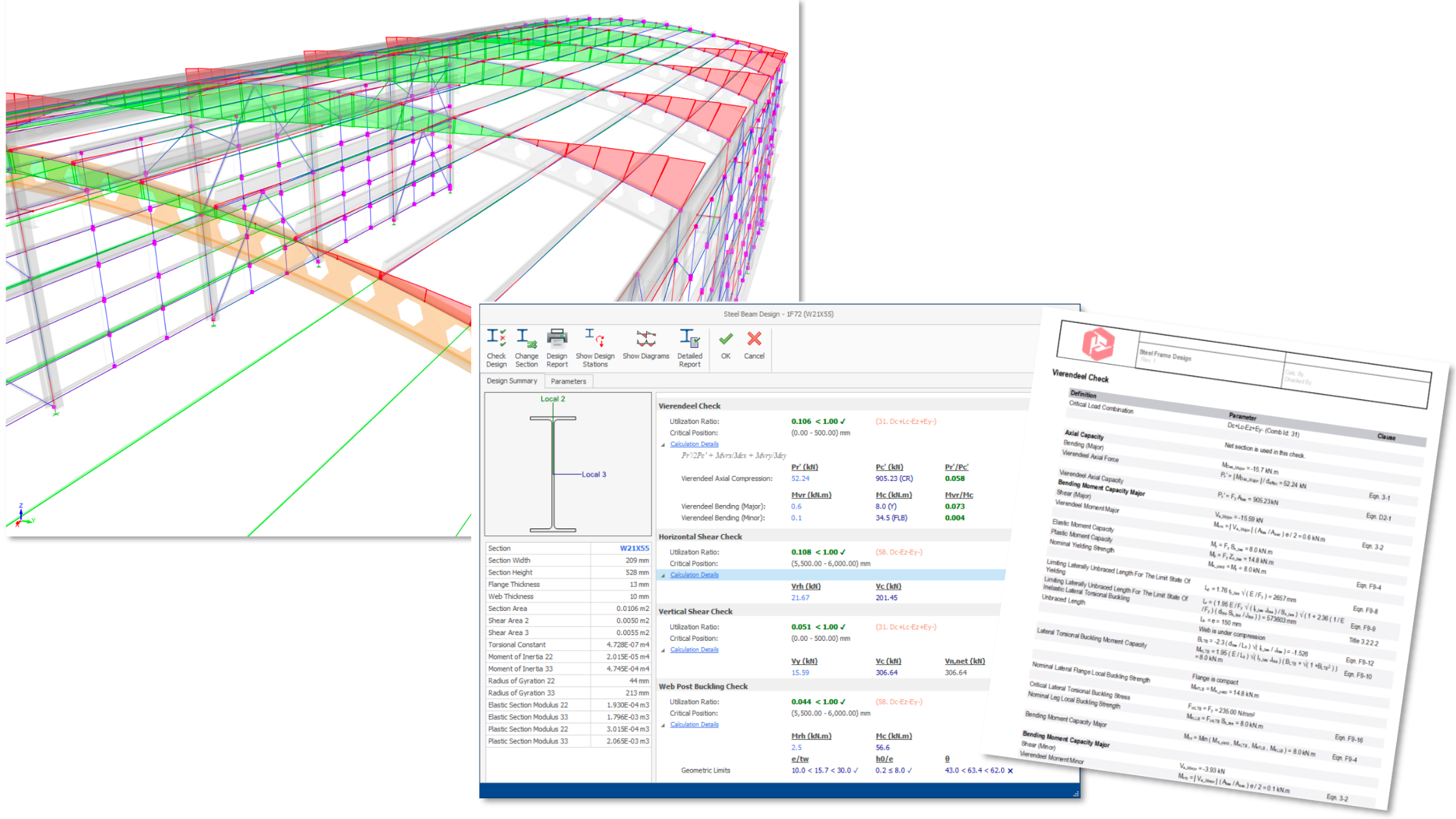

ProtaStructure 2025 performs comprehensive checks according to AISC360 and the Turkish Steel Design Code. While the current version supports non-composite castellated beams, Prota Software is actively working on adding support for Eurocode 3 and composite castellated beams in future updates.

Design Considerations

In the process of designing castellated or cellular beams, it is vital to thoroughly consider various failure modes, such as Vierendeel bending of tees, web post buckling, along with horizontal and vertical shear. These beams differ from simple solid-web members, as their design depends on a combination of global forces and localized forces at the web openings and posts.

Consequently, engineers must evaluate the following limit states:

- Compactness and local buckling

- Overall beam flexural strength

- Vierendeel bending of tees

- Web post buckling

- Axial tension/compression

- Horizontal shear

- Vertical shear

- Lateral-torsional buckling

Detailing and Support

ProtaStructure also facilitates the automatic communication of web openings to ProtaSteel for detailing purposes. This integration allows engineers to easily modify the openings as needed, ensuring the final design is accurate and efficient.

Conclusion

The ProtaStructure Design Guide for Castellated Beams Version 2.0 is an invaluable resource for engineers. With the enhanced capabilities of ProtaStructure 2025, users can confidently design and analyze these complex structural members, ensuring they meet the highest standards of safety and efficiency. For any further information or support, do not hesitate to contact Prota’s dedicated support team.

Thank you for choosing the ProtaStructure Suite. We are committed to helping you achieve excellence in your structural design projects.