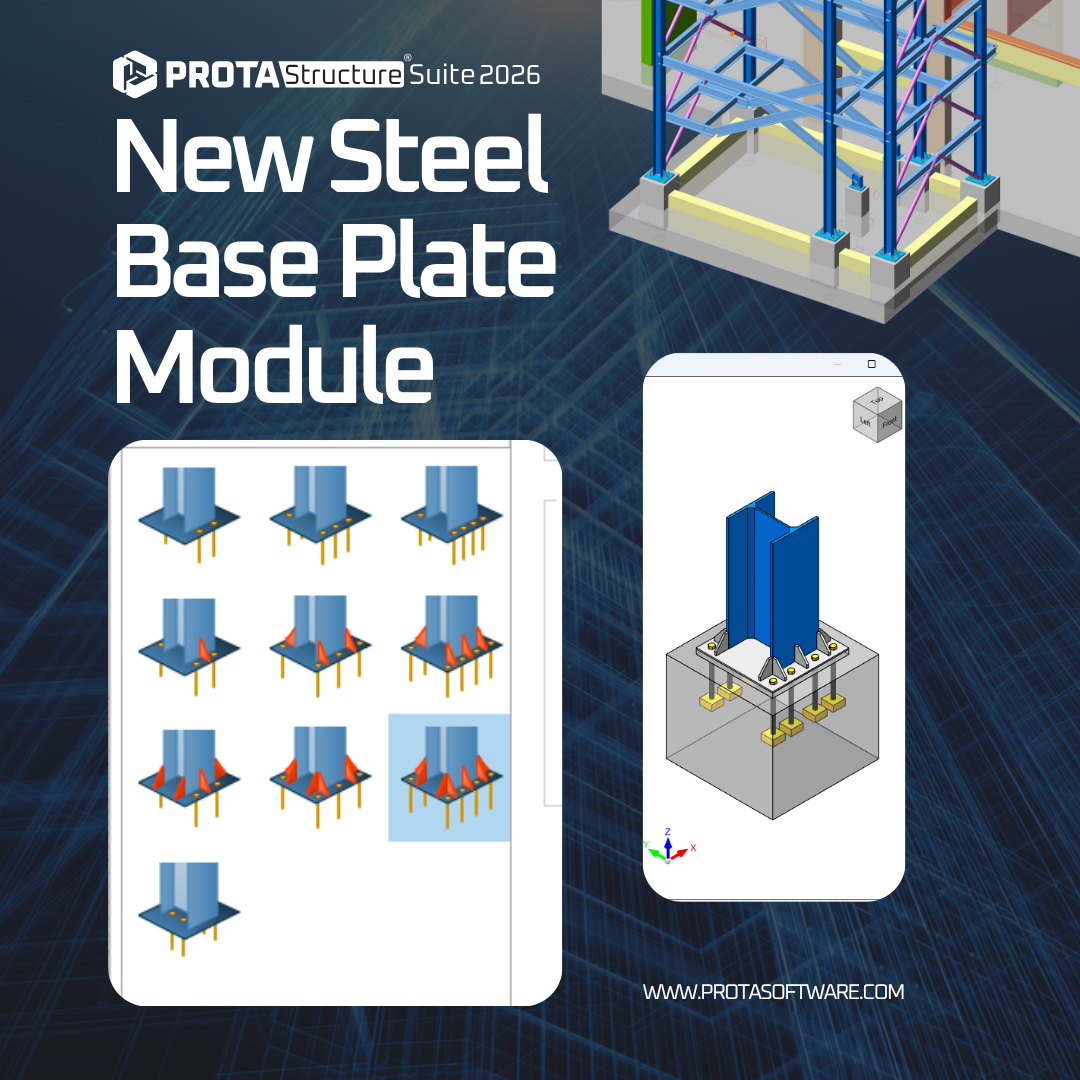

Advanced Steel Base Plate Design with ProtaStructure

Steel base plates form the vital link between steel columns and their supporting concrete foundations. They ensure that loads are transferred safely and efficiently while maintaining the structural stability of a building. Understanding how base plates are designed, analyzed, and detailed is crucial for every structural engineer.

What Are Steel Base Plates?

Steel base plates are flat steel elements welded to the bottom of steel columns. Their primary role is to distribute concentrated loads from columns into the concrete foundation below. Without them, localized crushing or instability can occur at the support level.

Base plates are not only structural components but also serve as the foundation for precise load transfer. They resist axial, shear, and moment forces, ensuring the column’s stability under varying load combinations.

Moreover, proper base plate design enhances durability, constructability, and cost-efficiency.

In this blog, we explore their functions, design principles, and how modern engineering tools such as ProtaStructure simplify and automate the process.

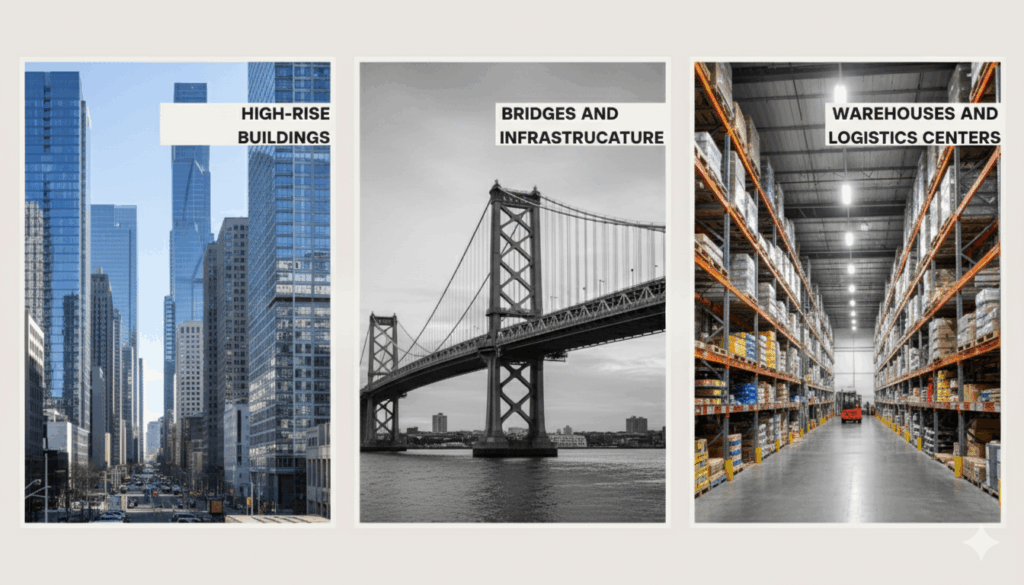

Use Cases

Steel base plates are essential in almost every steel-framed structure. However, their design requirements vary depending on the structural type, loading, and environmental conditions. Here are some key applications:

-

Industrial Buildings: Heavy machinery and cranes generate significant vertical and horizontal loads. Robust base plates are critical for stability.

-

High-Rise Buildings: Columns with large axial loads and slender profiles require base plates that distribute forces uniformly.

-

Bridges and Infrastructure: Base plates anchor steel girders and trusses, maintaining alignment and resisting uplift forces.

-

Warehouses and Logistics Centers: These buildings often feature repetitive column layouts with varying base plate geometries to suit load conditions.

-

Retrofit and Strengthening Projects: When existing foundations are reused, custom base plates help adapt new column configurations.

Each case demands careful attention to plate thickness, anchor bolt layout, and grout layer properties to ensure reliable performance.

How ProtaStructure Simplifies Base Plate Design

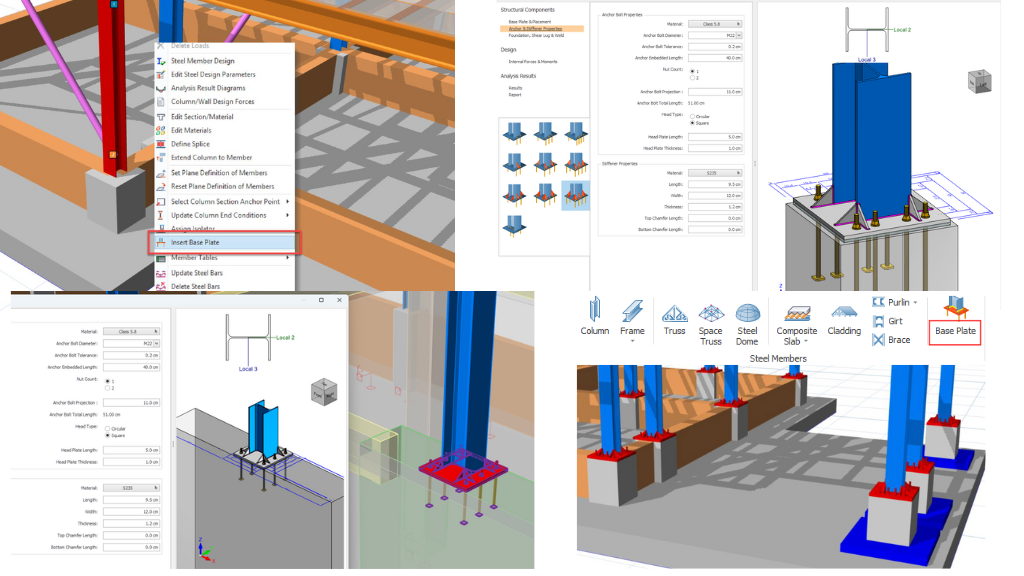

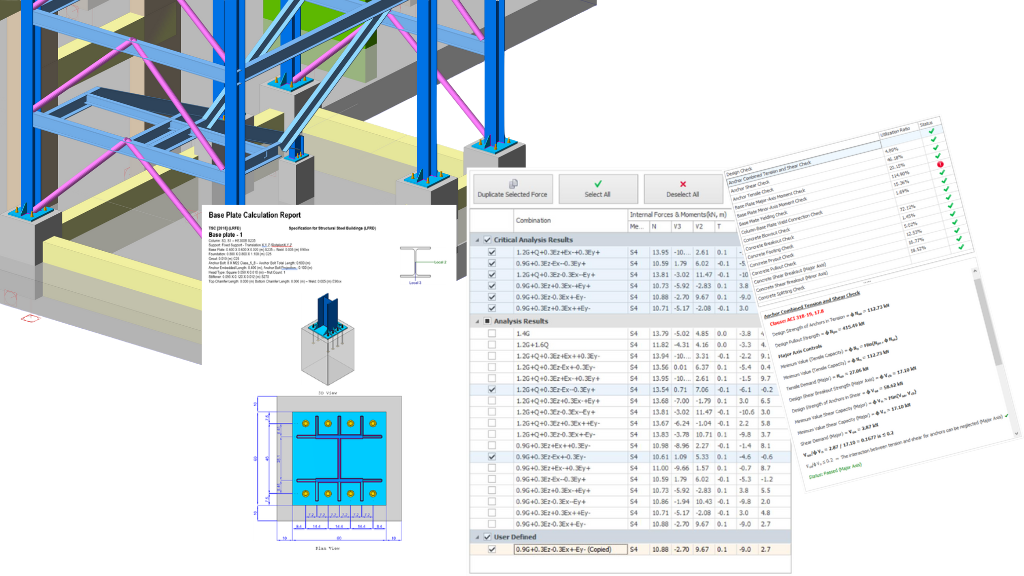

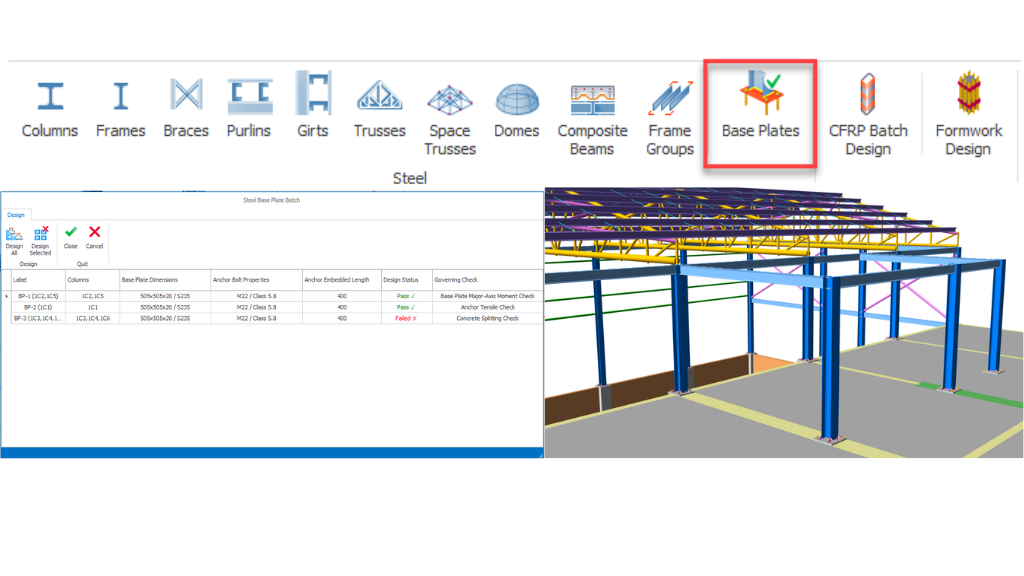

In ProtaStructure, steel base plate design is handled through a dedicated and fully integrated design macro. The module automates geometry definition, load extraction, and code-based verification.

The workflow is straightforward:

-

Select the steel column and define the connection parameters.

-

The software automatically generates the plate, anchor bolts, and grout interface.

-

Design checks are performed according to international codes su

-

ch as EN 1993-1-8 (Eurocode 3) and AISC Design Guide 1.

The integrated report includes:

-

Bearing pressure checks under service and ultimate limit states,

-

Bolt tension and shear verification,

-

Plate bending and weld strength checks.

Moreover, results can be visualized in both 2D and 3D, enabling engineers to understand stress distribution across the plate.

Therefore, users can confidently produce safe, code-compliant, and constructible designs in minutes.

Design Considerations

Effective base plate design requires balancing strength, stiffness, and practicality.

Key design aspects include:

-

Bearing Pressure Distribution: The plate must distribute column loads evenly without exceeding concrete bearing capacity.

-

Plate Thickness: Determined by bending under column loads. Thicker plates reduce deflection but increase cost.

-

Anchor Bolt Design: Must resist both uplift and shear forces while ensuring adequate edge distances.

-

Grout Layer: Acts as the interface between plate and foundation. Its thickness and compressive strength affect stress distribution.

-

Weld Detailing: Proper weld size and placement ensure the column-to-plate connection remains intact under all load cases.

However, engineers must also consider construction tolerances and field conditions. Therefore, using parametric tools like ProtaStructure helps ensure consistency and precision across multiple connections.

From Design to Detailing

Once design verification is complete, detailing becomes crucial. ProtaStructure automatically generates fabrication drawings that include:

-

Plate geometry and bolt layouts,

-

Weld sizes and symbols,

-

Foundation interface dimensions.

These details can be seamlessly exported to ProtaSteel and other CAD environments, ensuring interoperability throughout the project workflow.

Furthermore, Prota Software Help Center, for trainings and tutorials youtube channel provide ongoing technical support to help users achieve efficient, code-compliant designs.

Why It Matters

Steel base plates may seem like small components, yet they play an outsized role in the safety and performance of steel structures.

Understanding their behavior, selecting proper dimensions, and following international design standards are essential for reliable load transfer.

By using ProtaStructure, engineers can design, verify, and detail base plates faster and with higher accuracy. Consequently, projects benefit from better safety, reduced rework, and improved constructability.

To explore detailed methodologies and software capabilities, take a look at Steel Base Plate Design Guide and Version Comparison Sheet.

Unlock the full potential of ProtaStructure with our expert resources:

-

Prota Help Center – Tutorials, FAQs, and step-by-step guides.

-

ProtaStructure YouTube Channel – Feature demos, tips, and highlights.

-

Community Page – Connect, share, and learn with engineers worldwide.

-

Webinar Recordings – Catch up on training sessions you may have missed.

-

White Papers – Dive deeper into technical best practices.

-

Project Gallery – Explore real-world ProtaStructure projects.

-

Client Success Stories – Learn how others achieved results with ProtaStructure.