Istanbul New Airport Terminal Building Designed with ProtaStructure

Prota Engineering’s engineering and BIM teams used ProtaStructure throughout the entire Istanbul New Airport Terminal Building design phases. This approach allowed them to produce fast and safe models while minimizing human errors.

Overview

International engineering and BIM consultant, Prota Engineering, managed the structural design of the main passenger terminal building for the Istanbul New Airport. Appointed by the consortium of Cengiz, Kolin, Limak, MAPA, and Kalyon, the design team worked under tight schedule requirements to deliver exceptional results.

The Istanbul New Airport was designed as a modern, functional space with a unique identity. Despite its size, the terminal harmoniously integrates with its surroundings, featuring a clear horizontal expression. Prota Engineering delivered comprehensive seismic and structural design services for the project.

About The Project: Istanbul New Airport Terminal Design with ProtaStructure

Located 35 km from Istanbul on the Black Sea coast, the Istanbul New Airport is Turkey’s largest single investment. It aims to become the world’s busiest airport, serving 70 million passengers in its first year and over 150 million annually within 25 years. With a gross floor area exceeding 1.5 million square meters, the terminal building is the world’s largest airport under one roof.

The Challenges to Istanbul New Airport Terminal Design with ProtaStructure

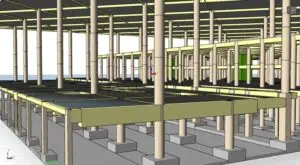

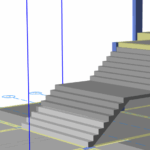

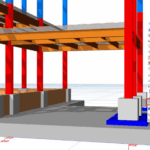

Prota Engineering faced tight deadlines and a complex structural design for the world’s largest airport terminal. The modern architectural design included curved facades, intricate steel roofs, and transfer slabs due to varying structural grids.

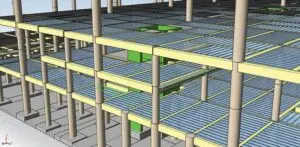

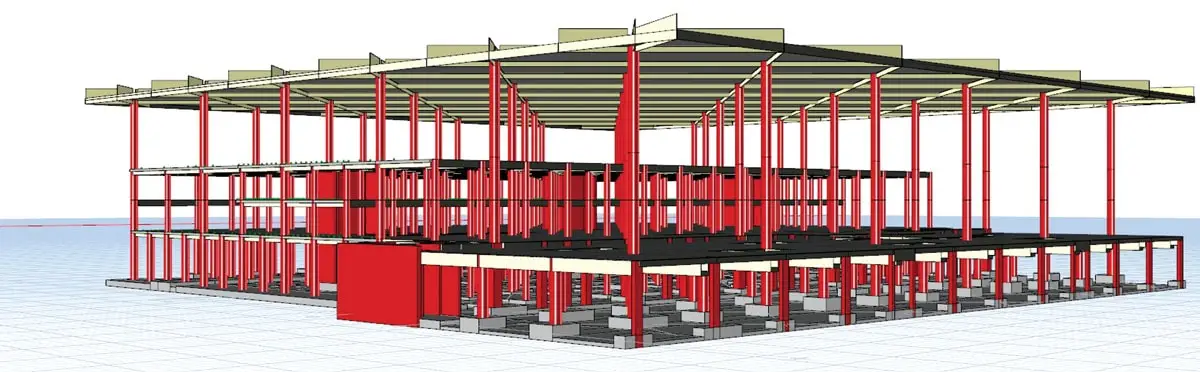

The terminal block, with a “T” shape measuring 760m x 414m, spans 260,000 m² and features reinforced concrete frames with precast slab panels. Partial mezzanine floors use steel frames and composite decks. The steel roof system rests on columns at 32m elevation, supported by a raft foundation and piles. ProtaStructure enabled engineers to handle these complexities efficiently.

The Solution: Istanbul New Airport Terminal Design with ProtaStructure

“ProtaStructure helped us reduce design time and increase project profitability. The project cost decreased by more than 50% thanks to fast, accurate, and automated design tools.”

— Gulsah SAGBAS Structural Team Leader

Sagbas added, “ProtaStructure is ideal for automating steel and concrete designs while ensuring compliance with earthquake regulations. We consistently achieve excellent results for complex projects like airports, residential buildings, hospitals, and shopping malls.”

Real-World Applications

Explore how ProtaStructure transforms engineering workflows:

Visit our Projects Gallery to see real-world applications.

Check out inspiring Customer Success Stories and our YouTube Channel.

Results

ProtaStructure’s Structural BIM design capabilities ensured project success by:

- Enabling quick assessment of design alternatives with rapid modeling,

- Delivering automated code-based design and earthquake detailing,

- Facilitating BIM integration for better team coordination,

- Allowing simultaneous modeling and design with model merge functionality,

- Reducing drafting efforts with automated detailing,

- Providing multi-language calculation reports to streamline communication.